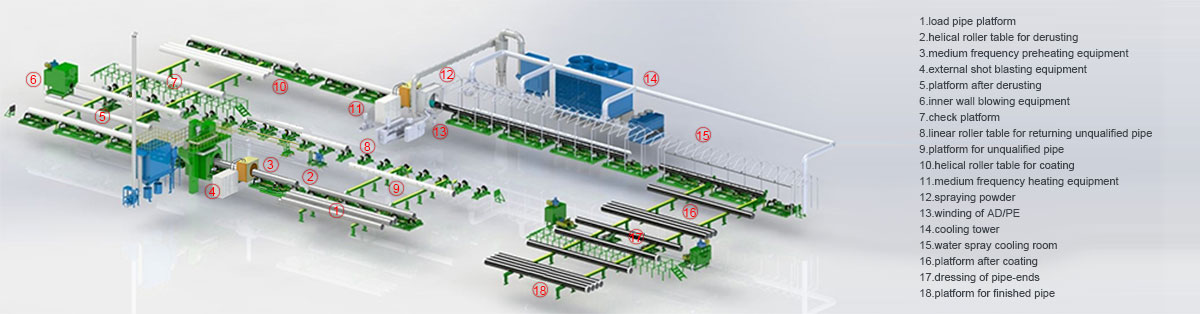

Pipeline external anticorrosion operating line

Steel pipe diameter:

φ76~

φ1219mm

Derusting grade:

Sa2.5 级

Profile Depth:

50~100μm

Cleaning ability:

≥400m2/h

Heat pipes to a temperature of 190 ~ 230 ℃, to prepare for the FBE coating and anticorrosion coating. Compared with traditional boiler heating system, pipes are heated evenly, clean and green.

USA Nordson Corporation automatic spraying system

Steel pipe diameter:

φ76~

φ1016mm

Coating thickness:

40~800μm

Spray gun number:24pieces

Powder spraying capacity:

≤400g/min/piece

Winding adhesive and polyethylene to the surface of gel state epoxy coating. Composed by a material handling system, AD extrusion and winding system, PE extrusion and winding system, extrusion die and its control system, guide roller system, etc.

Composed by cooling tower, water pump, spray cooling room, etc. By combination of quenching and slow cooling process, coated pipes are cooled to below 60 ℃. Water temperature drops through cooling tower and is recycled. No waste water discharge.

PE/PP coating is removed at pipe ends, suitable for pipeline welding construction. (take GB/T23257 for example, leave 100~150mm long for both ends, end face shall form a chamfer not larger than 45 degrees)

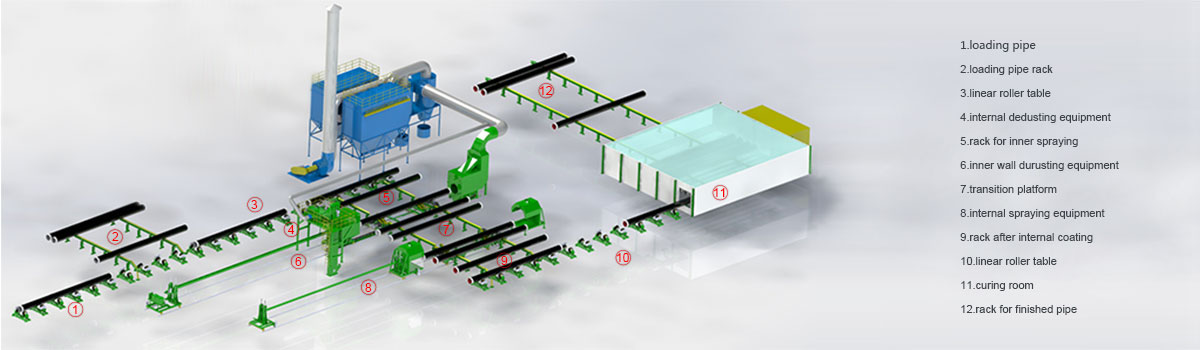

Pipeline internal anticorrosion operating line

Internal derusting apply to steel tube diameter φ108~φ529mm Internal coating apply to steel tube diameter φ108~φ508mm Spraying way is high-pressure airless spray, centrifugal spray. Heating the pipe coating in the curing room by the air heater.

Lab and test

Copyright ©2015 tpcoc.com.cn Powered By TPCOC Version 1.0.0